In a corner of a glass manufacturing factory, a quality inspector has been working for six hours straight. Under the harsh lighting, he struggles to spot the tiny imperfections on the glass with his naked eye. However, this scene is being completely transformed by a pair of "smart eyes" that never tire. Machine vision technology has not only freed workers from repetitive inspections but also raised the quality of glass manufacturing to unprecedented heights.

1. The Quality Inspection Revolution Brought by Machine Vision

Glass often has tiny bubbles or ripples. These flaws are now rare, thanks to advancements in machine vision technology and equipment. Traditional manual inspection is not only inefficient (3-5 pieces per minute) but also prone to human error. Now, Xincode Technology intelligent inspection equipment acts as an unflagging "super inspector," completing a full "check-up" of each piece of glass in just 1.5 seconds, with an astonishing precision of microns — equivalent to 1/70th of a human hair!

2. From Sand to Glass: The Perfect Journey of Manufacturing

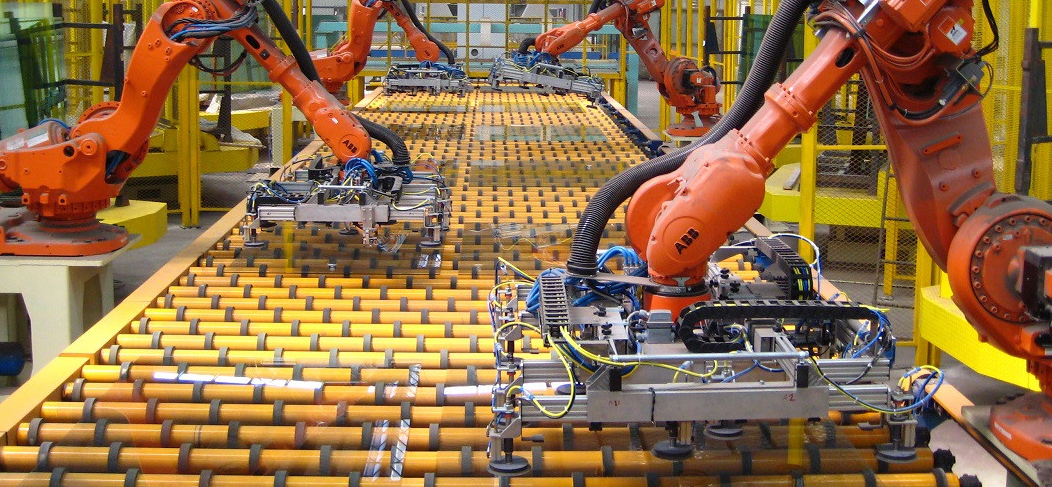

The creation of glass is like a magical journey: from ordinary sand to the flawless finished product, every step requires careful attention. Machine vision acts as a meticulous "guardian," starting from the raw material stage to ensure quality — it can detect impurities in raw materials, ensuring each batch meets production standards. During the glass forming process, Xincode high-speed cameras monitor the glass at hundreds of frames per second, catching any tiny scratches or air bubbles with its "eagle-eye."

3. Precision That Astonishes: How 3D Vision is Reshaping Glass Processing

In the automotive windshield manufacturing workshop, a worker is applying adhesive to a windshield. In the past, this job relied on the worker's extensive experience, and even a slight mistake could lead to an imperfect seal. Now, guided by 3D vision technology, the adhesive is applied precisely in just 3-5 seconds, with accuracy down to 0.1mm. This not only solves the problem of "hand tremors" but also saves tons of glue annually, making the process both eco-friendly and cost-effective.

4. A Revolution in Quality Management: From "Post-Inspection" to "Preventative" Measures

In the past, glass production was like "opening a blind box" — only at the final inspection could the quality be determined. Today, machine vision systems not only detect issues but also predict potential problems through big data analysis. This "preventative" intelligent management approach has drastically reduced defect rates, and workers no longer have to panic when unexpected quality issues arise.

Conclusion: Let the Light of Technology Illuminate Every Detail of Manufacturing

When we hold a crystal-clear glass in our hands, we rarely think about the technology behind it. Machine vision acts as a quiet "quality guardian," using its precision and dedication to transform ordinary glass into a work of art. This is not just technological progress; it's a relentless pursuit of perfection. Next time you touch a flawless piece of glass, take a moment to consider how much wisdom and craftsmanship have gone into it. Is your industry also undergoing such an intelligent transformation? Xincode Technology offers machine vision solutions for various industries, providing strong momentum for the digital and high-quality development of businesses and offering optimized product solution combinations for enterprise upgrades.

Please select your service type and leave your information so that we can provide the appropriate service. Xincode looks forward to working with you.